The ammonia decomposition hydrogen production unit takes liquid ammonia as raw material, and after gasification, it is heated and decomposed under the action of catalyst to produce a mixture containing 75% hydrogen and 25% nitrogen. Pure hydrogen with purity of 99.99% can be further prepared by pressure swing adsorption.

Технические характеристики продукта

Технические характеристики продуктаRaw material ammonia

Dew Point: ≤ – 10 °C

Pressure :0 . 05Mpa

Standard: International first-class or above

Product decomposition gas

Dew point : ≤ – 6 0 °C

Ammonia residual: 2 ppm

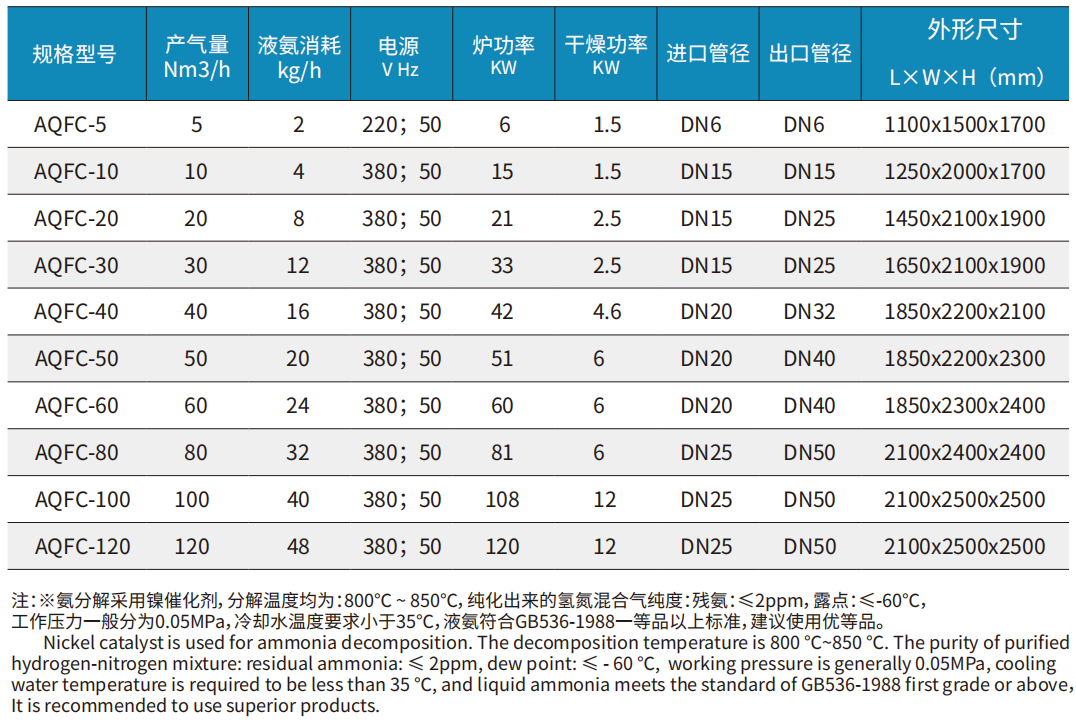

Decomposition gas capacity: 5 – 300Nm3/h

Simple principle, compact structure, small floor area and easy operation;

Low investment, low energy consumption and low operation cost;

It is widely used to meet the needs of most hydrogen applications;

The core components, furnace body, furnace liner and electric heating wire, are optimized and guaranteed for three years under normal working conditions;

Good thermal insulation effect, power saving and convenient maintenance;

Long service life, no deformation of furnace;

Automatic purification power failure or air compressor shutdown, ammonia decomposition does not stop;

The emission time of regenerated waste gas is short, saving regenerated ammonia;

Intelligent human-computer interaction, easy operation, intuitive data, and settable drying tower conversion time.