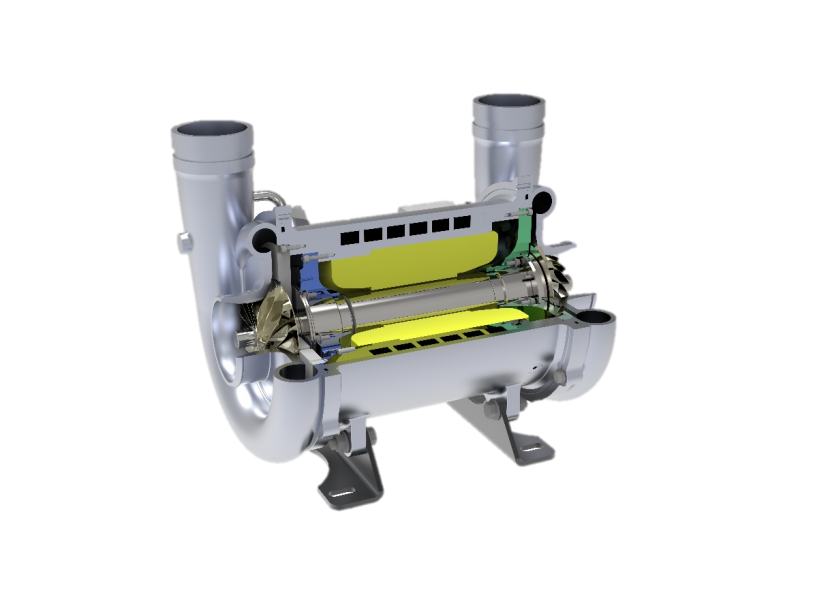

The small cyclone ultra-high-speed centrifuge adopts the direct drive structure of high-speed permanent magnet synchronous motor, and integrates the centrifugal impeller and motor drive. It achieves contact-free rotor suspension with high-precision air foil bearings.

The main function of permanent magnet synchronization is to drive the rotation of the rotating shaft. It generates a current with controllable frequency through the inverter, and inputs this current into the motor stator to generate a rotating magnetic field, driving the rotating shaft to rotate at high speed.

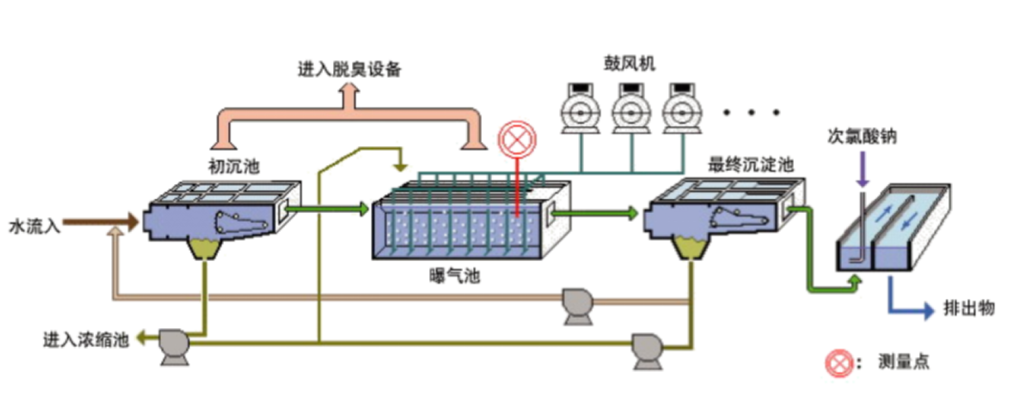

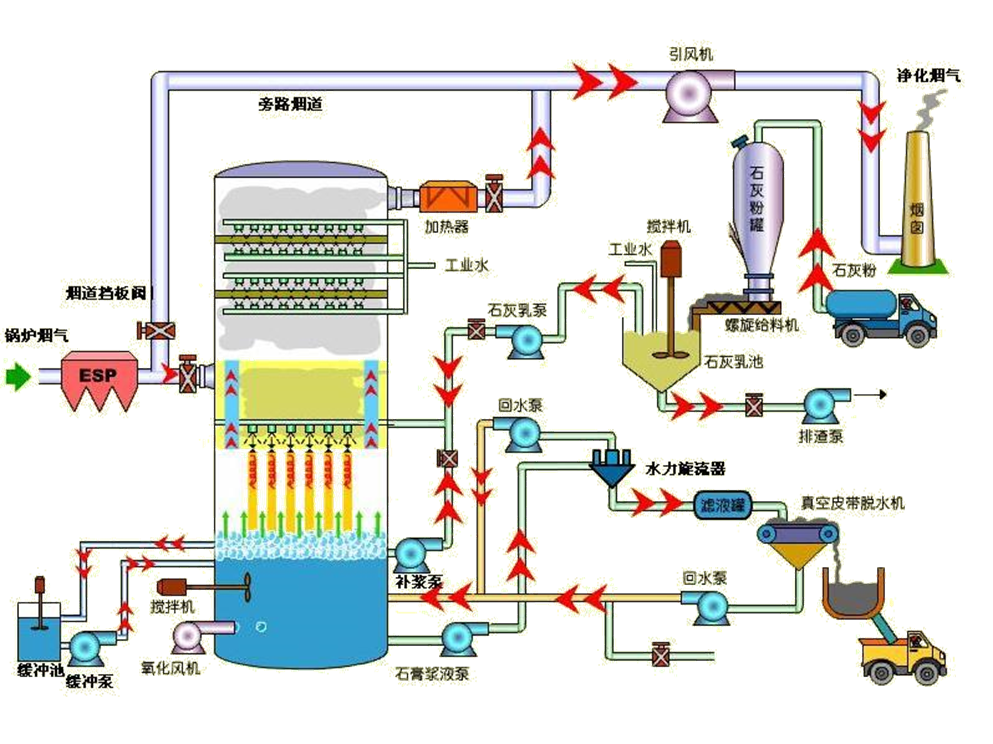

The main function of the fan is to realize the air blast, and the impeller that rotates at high speed with the rotating shaft drives the air to enter from the air inlet of the volute, and the air becomes the gas with a certain flow rate and pressure under the guidance and pressurization of the volute, and finally blows out from the air outlet of the volute, so as to realize the air blast of the fan.

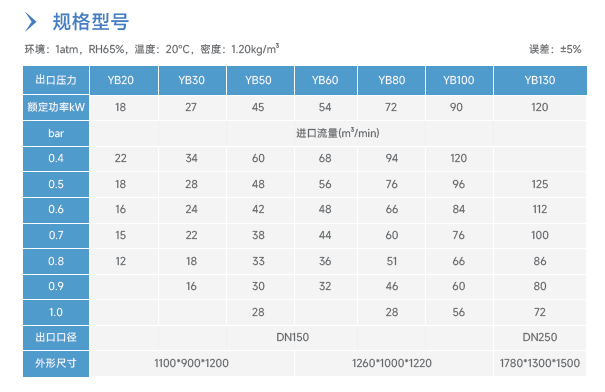

Product Specifications

Product Specifications

1. Structural characteristics of small cyclone ultra-high-speed centrifugal blower

(1) Product advantages

1. Vehicle specification level – using hydrogen fuel cell supporting ultra-high-speed air suspension host, it has passed 300,000 start-stop verification, 120,000 rpm maximum speed verification, and durability verification;

The small cyclone model adopts the main head design to represent the key technology research and development level and innovation ability of the ultra-high-speed air suspension blower in the industry, overcoming the disadvantages of double air outlet convection, the reduction of the total efficiency of the whole machine, the main engine performance of the vehicle level, the full dynamic pressure air suspension bearing, and more than 300,000 times of durable start-stop life test, which reduces the failure point to ensure the stable and safe operation of the machine.

1.2 The full range of ultra-high-speed air suspension blower products are more intelligent and stable PLC control system

The control system is purchased from the world’s leading PLC programmable logic controller, which should be scalable, anti-interference and corrosion-resistant. The point-to-point communication rate is efficient, the machine runs more stable, the speed is accurately controlled, the cheap single-chip microcomputer circuit board is eliminated, the single-chip microcomputer signal transmission rate is low, it is not easy to repair, once damaged, it must be replaced as a whole, and the blower increases the maintenance cost of the owner in the later stage of operation, and there is no scalability. Panels are susceptible to air corrosion causing serious failures. And it is easy to be affected by signal interference, resulting in wrong actions, such as internal current interference of the inverter, resulting in sudden shutdown, display data confusion, screen dead pixels, screen no data display, etc.

1.3 100% oil-free design

The use of full dynamic pressure air suspension bearings ensures the high quality of the gas: oil-free, water-free, clean and dry. It not only meets the requirements of high-quality gas consumption at the customer’s site, but also simplifies the post-treatment procedure, while also reducing procurement and maintenance costs.

(2) Technical advantages

2.1 Patented design of the whole machine

The unique design of “L” air intake duct is more optimized, and the closed air intake is more efficient.

2.2 High performance

Through advanced aerodynamic design and analysis, a high-performance impeller is designed to optimize the design using the latest technology

Using 3D computational fluid dynamics analysis to maximize the air efficiency of the impeller Low-speed vibration from the aviation industry, dynamic analysis technology makes the design of the rotor more optimized, using AxSTREAM software for optimization design and analysis, successfully solving a variety of problems such as cooling and heat transfer, high-performance open radiant impeller & shaft, in order to achieve the best efficiency and stability, the high-speed rotating impeller is accurately balanced and accurately designed; The motor outputs the power energy of mechanical rotation to drive the impeller, which sucks in the gas from the axial direction and discharges the gas from the radial direction of the impeller; Open radiant impeller is used to achieve a wide adjustment range (adjustment range reaches 50%~100%); The impeller is made of corrosion-resistant aluminum alloy (AL7075), which has long life, low vibration and low noise; The impeller has passed the 120% overspeed rotation test to ensure higher reliability

2.3 Long life bearings

The air suspension blower consists of a combination of radial air bearings and thrust air bearings.

Through the principle of pneumatic design, high-speed rotation is applied to form an air film between the shaft and the bearing.

No contact and friction air bearings for maximum energy efficiency, 100% oil-free air lubricating oil system;

2.4 PLC automatic control system of operation interface

The control screen displays all key data, including: temperature, pressure and flow, motor data, etc.;

Early warning and parameter modification to help eliminate unplanned downtime;

Monitor critical parameters related to downtime to prevent component damage;

2.5 Cooling system (fully automatic cooling)

In high-speed rotation, the motor and compression section are cooled by the built-in condensate self-circulation system to ensure efficient operation over the entire operating range

The simple design ensures excellent durability even under extreme operating conditions

2.6 Convenient control

The artistic design provides a user-friendly interface for easy monitoring and sophisticated control

Large color touch screen display

All blower parameters are displayed logically, which is convenient for the user to operate.

Provides real-time operating status and a clear parameter interface.

The blower is designed to provide easy on/off buttons.

2.7 Creative Design

It is designed for overall installation design, which meets the convenience of installation, assembly and maintenance.

The overall installation design has the advantage of being easy to install and maintain

Cable connection The main motor and the motor start cabinet, the control cabinet and the high-voltage control cabinet are connected by a simple control line installation

The main motor and support frame facilitate simple installation and minimize installation space

Automatic cooling system